People ask

me whether RFID is going to replace barcoding, the differences being barcodes

require a line of site for the scanner, and barcodes hold a lot less data than

RFID chips. They are separate tools depending on the application – an analogy

sort of like choosing a fork or a spoon.

Both technologies will be used for the foreseeable future.

Radio Frequency Identification (RFID) is often touted as groundbreaking new technology, when it has been around since WWII. In 1935 a Scottish innovator sent radio waves from a ground-based transmitter to an aircraft antenna which was then decoded to determine the aircraft’s identity.

The label company I worked for back in the 1990’s used to do R&D for an anti-theft RFID company called Checkpoint Systems, out of Thorofare, NJ. We also supplied the library cards and cover labels with embedded foil, for their library self-checkout and anti-theft systems. When the patron checked out and walked past the RFID antennas the RFID system logged the exact book titles. Prior to that time the librarians at checkout would scan the books then insert a due date card inside of each book’s cardholder pocket. The cards would act as a “cover up label”. In this case the cover up label simply had embedded foil sandwiched between paper so when passing by the antenna, it would not trigger an alarm. Fast forward 30 years and today’s RFID systems are much smarter.

Today, one popular RFID application involves tagging products so a shopping cart full of goods can pass by an RFID antenna, and all products are scanned instantaneously. Over the years, the price of RFID tags has decreased, making their use on lower priced merchandise possible. For example, it would not make sense to place a .25 cents tag on a can of peas for self-checkout purposes. On the other hand, what if that can of peas needed to have its history traced (total traceability) from the picking of the peas, all the way to the store shelf? In this case, the tag price becomes less of an issue.

Another common RFID application is asset tracking. Since a line of sight is not required for RFID scanning, a person can walk around a room and scan all inventory within range (typically 1 meter) of the reader. Contrast this with barcoding, where each individual asset would need to have its barcode scanned from inches away. When folks tell stories about how someone can take inventory by simply pointing an RFID reader around the room, that would only be true with active RFID tags (they have to emit a signal like a beacon). Then each tag would need to be powered and the cost is over $50 per label. Most RFID tags in use today are passive and are priced in the $0.25/label range; no power required.

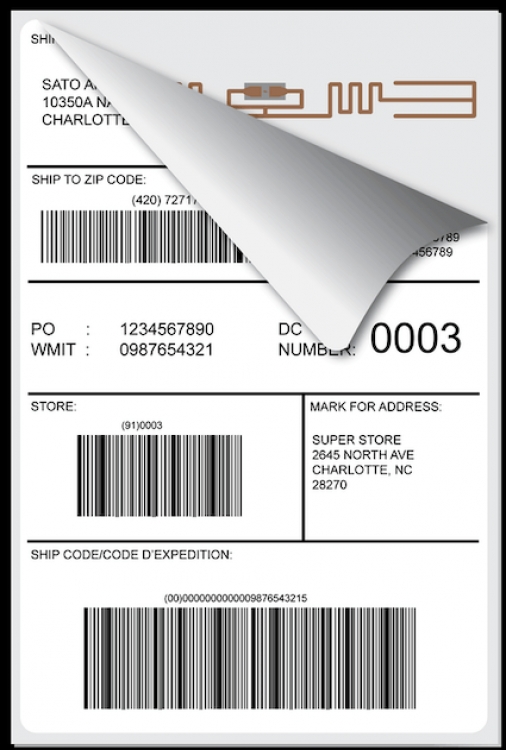

My company, RighterTrack, offers RFID applications and solutions for meeting RFID label mandates. For example, a manufacturer or distributor who sells to Walmart or the DoD is required to use RFID on shipping labels, and on individual (item level) products.

RighterTrack will analyze your requirements, provide sample RFID labels you submit for approval, then provide you with your own desktop label printer with RFID encoding, design software, and RFID tags. We provide training, support what we sell, and have earned new business strictly from referrals the past 22 years.

Our solutions support EPC, ISO, I-Code, Rain, and Tag-it standards. For help and to discuss your RFID label application, call or email me today at 215-493-7191 or info@rightertrack.com.

Note: This article was created and edited by a human!

Published: