Special printing inks can provide plenty of functional solutions for providing visual evidence and detecting that something has occurred. That “something” could be tamper evidence, expiration, exposure, and levels of exposure.

The example that most people are aware of are the dipping test strips that measure chemical levels in swimming pools and spas. Results are based on color matches that fall within particular ranges.

Here are six other examples where chemically treated inks provide cool functionality for visual evidence:

Time

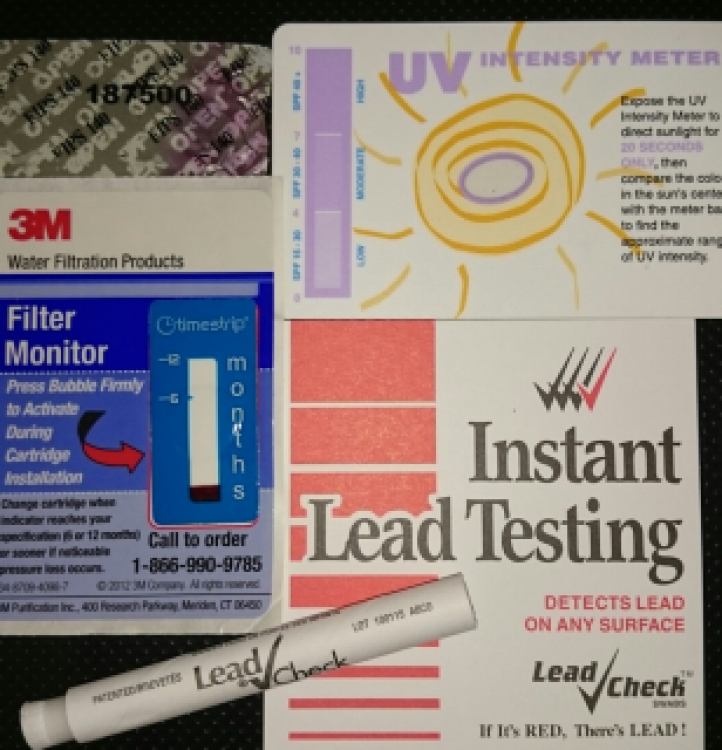

Inks can be made to change color over a certain period of time. The beer companies have been using this as a “freshness” gauge. My water filter company utilizes times trips that can denote the age of the filter, so I know when it's time to change it.

UV

Inks can detect the level of UV rays. A UV intensity meter card can be used to find the approximate range of UV intensity.

Temperature

Inks can be made to change color at certain temperatures. Medical companies have used this to confirm equipment sterilization for years. For tamper evident applications, inks can be made to turn certain colors and stay that way if heat is applied.

Lead

Inks can be made to detect levels of toxic lead in paint, dinnerware, etc. My instant lead testing kit boasts “if it’s red, there’s lead.” The suspected area or item is swabbed then rubbed onto a test area. If lead is on the swab, the test area will turn red.

Radiation

Inks can be made to detect the level of exposed radiation. The RADTriage Radiation Detector is a U.S. Military-grade personal dosimeter that instantly detects radiation exposure in the event of radiation exposure. This always-on wallet card/badge radiation detector does not require batteries or calibration. The sensor strip instantly turns darker when it detects harmful levels of radiation.

Liquid

Inks can be made that will change color if moisture reaches a certain level. Apple has been using liquid water sensors in their iphones to void warranties due to water damage. These are simply printed stickers, or sensor stickers for you fancy folks.

Have you found any other uses for specialty detection inks, or are wondering about incorporating something like this to help your business? Contact RighterTrack today 215-493-7191 or e-mail

Published: